Ürünler

MGP New Compact Tri-rod Cylinder(Ø20~Ø100)

Features

1. Light weight and compact.

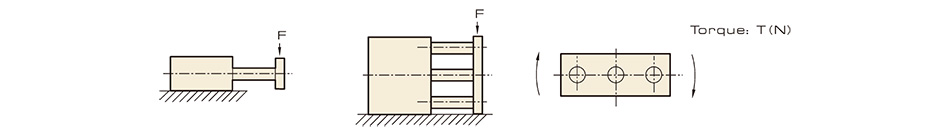

2. Strong transverse load capacity.

3. Strong torque capacity.

4. High Non-rotating precision.

5. Either ball joint or slide joint are available for directional bearing for directional rod.

6. Easy for installation.

7. Position of both side ports are changeable.

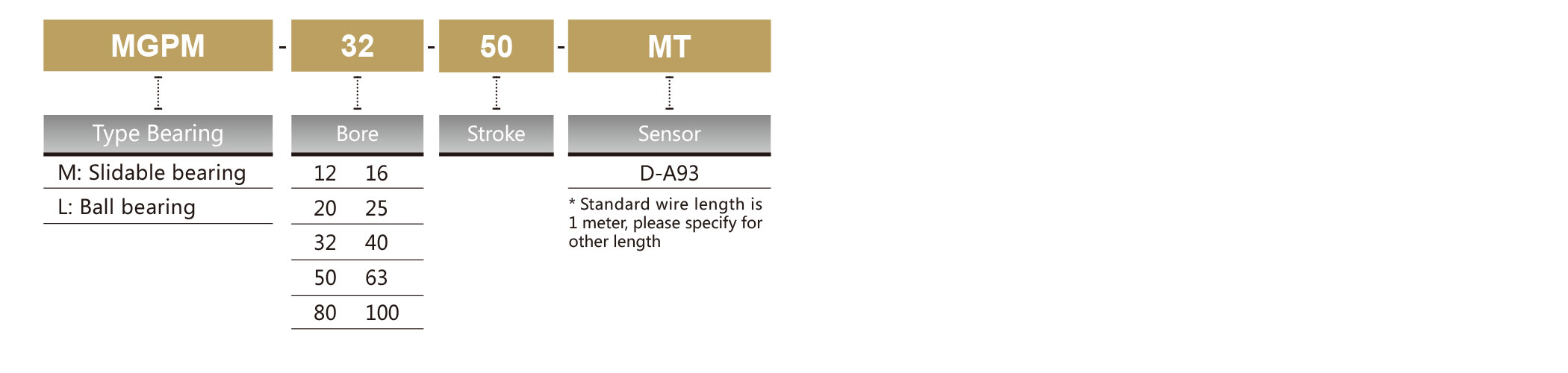

Ordering Code

Ordering Code: (examples)

● Cylinder dia needed: 12,stroke: 50, slid able bearing.Right model number: MGPM 12-50

● Cylinder dia needed: 40, stroke: 100,Ball bearing with two sensor switches, lead wire length 0.5 m. Right model number: MGPL 40-100-MT2

Specification

Bore (mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

Operation Fluid | Air | ||||||||||

Operation | Double Acting | ||||||||||

Anti-pressure testing pressure | 1.5 MPa (15.3 kgf/cm²) | ||||||||||

Max. Operation Pressure | 1.0 MPa (10.2 kgf/cm²) | ||||||||||

Min. Operation Pressure | 0.12 MPa (1.2 kgf/cm²) | ||||||||||

Ambient and fluid temperature | 5 ~+60 ℃ | ||||||||||

Piston Speed | 50~500 mm/s | 50~400 mm/s | |||||||||

Buffer | Rubber Buffer | ||||||||||

Stroke Tolerance | +1.5 mm 0 | ||||||||||

* Lubrication | Non-lub | ||||||||||

Bearing | Slidable bearing/Ball Bearing | ||||||||||

Non-rotating rod precision | Slidable bearing | ± 0.08° | ± 0.07° | ± 0.06° | ± 0.05° | ± 0.04° | |||||

Ball Bearing | ± 0.10° | ± 0.09° | ± 0.08° | ± 0.06° | ± 0.05° | ||||||

Port Size Rc (PT) | M5×0.8 | 1/8″ | 1/4″ | 3/8″ | |||||||

*If lubricant is demanded, please choose clear No.1 lubricant, ISOVG32.

Stroke

Bore (mm) | Standard Stroke (mm) | ** Sensor Switch Optional Model (For slide installation) |

12 , 16 | 10 , 20 , 30 , 40 , 50 , 75 , 100 | D-Z73L D-Z76L D-Z80L D-Y59AL D-Y59BL |

20 , 25 | 20 , 30 , 40 , 50 , 75 , 100 , 125 , 175 , 200 | |

32 , 40 , 50 , 63 , 80 , 100 | 20 , 50 , 75 , 100 , 125 , 150 , 175 , 200 |

* Strokes(from 5, 10, 20, 30, 35……)are added with 5, 10, 15, 20 mm thick gasket respectively, ex: MGPM50-10 is with 15 mm thickness gasket (MGPM50-25).

** Please refer to sensor switch series pages in this catalog for spec. and characteristic. Code for lead wire length as follow: Blank – 0.5 m, L-3 m. Example: D-Y59AL, D-Y59AL.

Load and Torque

Bore (mm) | Sreies | Max. Transverse LoadF(N) | |||||||||||

Stroke (mm) | |||||||||||||

10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | ||

12 | MGPM | 24 | 19 | – | 17 | 14 | 13 | 26 | 22 | – | – | – | – |

MGPL | 37 | 27 | – | 22 | 35 | 30 | 23 | 18 | – | – | – | – | |

16 | MGPM | 38 | 31 | – | 27 | 23 | 21 | 37 | 32 | – | – | – | – |

MGPL | 54 | 40 |

| 32 | 54 | 47 | 35 | 28 | – | – | – | – | |

| 20 | MGPM | – | 49 | – | 43 | 38 | 35 | 87 | 75 | 66 | 59 | 54 | 49 |

MGPL | – | 58 | – | 48 | 101 | 90 | 70 | 58 | 62 | 54 | 48 | 43 | |

25 | MGPM | – | 69 | – | 60 | 54 | 49 | 116 | 100 | 88 | 79 | 71 | 65 |

MGPL | – | 82 | – | 68 | 132 | 118 | 93 | 77 | 80 | 70 | 62 | 55 | |

32 | MGPM | – |

| 203 | – | – | 164 | 182 | 159 | 142 | 127 | 116 | 106 |

MGPL | – | – | 113 | – | – | 78 | 130 | 107 | 130 | 114 | 101 | 90 | |

40 | MGPM | – | – | 203 | – | – | 164 | 182 | 159 | 142 | 127 | 116 | 106 |

MGPL | – | – | 113 | – | – | 78 | 129 | 106 | 130 | 114 | 101 | 90 | |

50 | MGPM | – | – | 296 | – | – | 245 | 273 | 241 | 216 | 195 | 179 | 164 |

MGPL | – | – | 120 | – | – | 83 | 178 | 148 | 148 | 129 | 114 | 102 | |

63 | MGPM | – | – | 296 | – | – | 245 | 273 | 241 | 216 | 195 | 179 | 164 |

MGPL | – | – | 117 | – | – | 81 | 176 | 145 | 145 | 126 | 111 | 99 | |

80 | MGPM | – | – | 352 | – | – | 297 | 368 | 329 | 298 | 272 | 251 | 232 |

MGPL | – |

| 125 | – | – | 99 | 281 | 240 | 208 | 184 | 163 | 147 | |

100 | MGPM | – | – | 515 | – | – | 445 | 498 | 450 | 410 | 377 | 349 | 325 |

MGPL | – |

| 138 | – | – | 108 | 395 | 340 | 297 | 263 | 235 | 211 | |

Max. Forque T (N*m) | |||||||||||

Stroke (mm) | |||||||||||

10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 175 | 200 |

0.39 | 0.32 | – | 0.27 | 0.24 | 0.21 | 0.43 | 0.36 | – | – | – | – |

0.78 | 0.66 | – | 0.57 | 0.93 | 0.85 | 0.69 | 0.58 | – | – | – | – |

0.69 | 0.58 | – | 0.49 | 0.43 | 0.38 | 0.69 | 0.58 | – | – | – | – |

1.23 | 1.06 | – | 0.92 | 1.53 | 1.40 | 1.16 | 0.99 | – | – | – | – |

– | 1.05 | – | 0.93 | 0.83 | 0.75 | 1.88 | 1.63 | 1.44 | 1.28 | 1.16 | 1.06 |

– | 1.70 | – | 1.52 | 3.06 | 2.87 | 2.47 | 2.17 | 2.38 | 2.16 | 1.98 | 1.82 |

– | 1.76 | – | 1.55 | 1.38 | 1.25 | 2.96 | 2.57 | 2.26 | 2.02 | 1.83 | 1.67 |

– | 2.80 | – | 2.53 | 4.67 | 4.39 | 3.81 | 3.36 | 3.65 | 3.31 | 3.02 | 2.78 |

– | – | 6.35 | – | – | 5.13 | 5.69 | 4.97 | 4.42 | 3.98 | 3.61 | 3.31 |

– | – | 4.76 | – | – | 3.86 | 6.53 | 5.75 | 7.10 | 6.46 | 5.92 | 5.47 |

– | – | 7.00 | – | – | 5.66 | 6.27 | 5.48 | 4.87 | 4.38 | 3.98 | 3.65 |

– | – | 5.24 | – | – | 4.25 | 7.19 | 6.33 | 7.81 | 7.11 | 6.52 | 6.02 |

– | – | 13.0 | – | – | 10.8 | 12.0 | 10.6 | 9.50 | 8.60 | 7.86 | 7:24 |

| – | 7.02 | – | – | 5.76 | 12.3 | 10.9 | 11.2 | 10.2 | 9.40 | 8.69 |

– | – | 14.7 | – | – | 12.1 | 13.5 | 12.0 | 10.7 | 9.69 | 8.86 | 8.16 |

– | – | 77.7 | – | – | 6.35 | 13.7 | 12.2 | 12.5 | 11.4 | 10.5 | 9.65 |

– | – | 22.0 | – | – | 18.6 | 22.9 | 20.5 | 18.6 | 17.0 | 15.6 | 14.5 |

– | – | 10.3 | – | – | 9.35 | 24.8 | 22.7 | 20.9 | 19.4 | 18.0 | 16.9 |

– | – | 38.8 | – | – | 33.5 | 37.5 | 33.8 | 30.9 | 28.4 | 26.2 | 24.4 |

– | – | 13.6 | – | – | 12.2 | 41.1 | 37.9 | 35.1 | 32.7 | 30.5 | 28.6 |

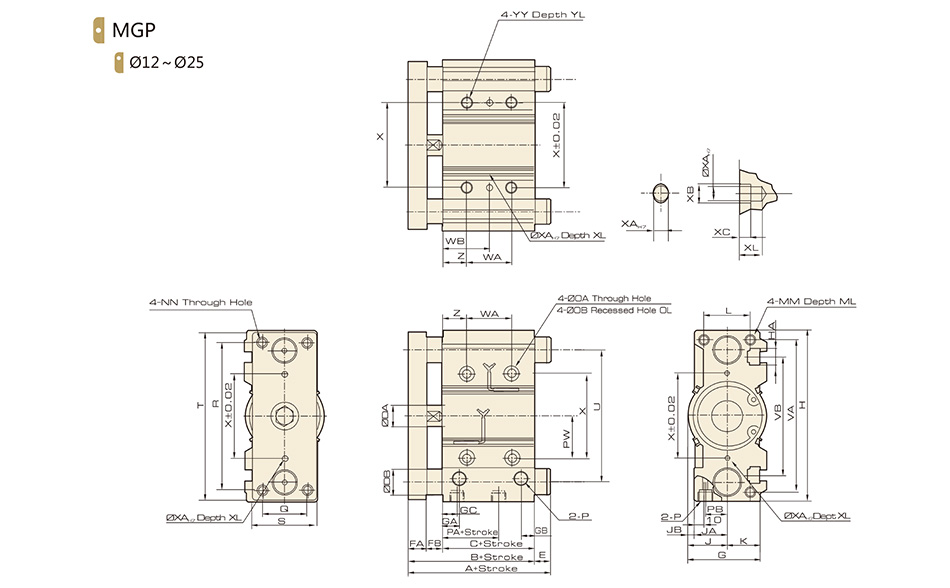

Overall Dimension

Dimension

MGPM, MGPL (Ø12~Ø25)

Bore (mm) | Standard Stroke | B | C | DA | FA | FB | G | GA | GB | H | HA | J | K | L | MM | ML | NN OA OB | OL | P | PA | PB | PW | Q | ||

12 | 10,20,30,40, | 42 | 29 | 6 | 8 | 5 | 26 | 11 | 7.5 | 58 | M4 | 13 | 13 | 18 | M4×0.7 | 10 | M4x0.7 | 4.3 | 8 | 4.5 | M 5×0.8 | 13 | 8 | 18 | 14 |

16 | 50,75,100 | 46 | 33 | 8 | 8 | 5 | 30 | 11 | 8 | 64 | M4 | 15 | 15 | 22 | M5×0.8 | 12 | M 5×0.8 | 4.3 | 8 | 4.5 | M 5×0.8 | 15 | 10 | 19 | 16 |

20 | 20,30,40,50, 75,100,125, 150,175,200 | 53 | 37 | 10 | 10 | 6 | 36 | 10.5 | 8.5 | 83 | M5 | 18 | 18 | 24 | M5×0.8 | 13 | M 5×0.8 | 5.6 | 9.5 | 5.5 | Rc1/8 | 12.5 | 10.5 | 25 i | 18 |

25 | 53.5 | 37.5 | 12 | 10 | 6 | 42 | 11.5 | 9 | 93 | M5 | 21 | 21 | 30 | M6×1.0 | 15 | M6xl.O | 5.6 | 9.5 | 5.5 | Rc1/8 | 12.5 | 13.5 | 28.5 | 26 | |

Bore(mm) | Standard Stroke | R | S | T | U | VA | VB | WA |

| WB | X | XA | XB | XC | XL | YY | YL | Z | |||

| Below 30st | 40st to 100st | 125st or above | Below 30s | 40st to 100st | 125st or above | ||||||||||||||||

12 | 10,20,30,40, 50,75,100 | 48 | 22 | 56 | 41 | 50 | 37 | 20 | 40 | – | 15 | 25 | – | 23 | 3 | 3.5 | 3 | 6 | M5x0 8 | 10 | 5 |

16 | 54 | 25 | 62 | 46 | 56 | 38 | 24 | 44 | – | 17 | 27 | – | 24 | 3 | 3.5 | 3 | 6 | M5x0.8 | 10 | 5 | |

20 | 20,30,40,50,75, 100,125,150,175,200 | 70 | 30 | 81 | 54 | 72 | 44 | 24 | 44 | 120 | 29 | 39 | 77 | 28 | 3 | 3.5 | 3 | 6 | M6xl.O | 12 | 17 |

25 | 78 | 38 | 91 | 64 | 82 | 50 | 24 | 44 | 120 | 29 | 39 | 77 | 34 | 4 | 4.5 | 3 | 6 | M6xl.O | 12 | 17 | |

MGPM (Slidable Bearing)

Bore (mm) | A |

DB | E | ||

Below 50st | Above 50st | Below 50st | Above 50st | ||

12 | 42 | 60.5 | 8 | 0 | 18.5 |

16 | 46 | 64.5 | 10 | 0 | 18.5 |

20 | 53 | 84.5 | 12 | 0 | 31.5 |

25 | 53.5 | 85 | 16 | 0 | 31.5 |

MGPL (Ball Bearing)

Bore(mm) | A | DB | E | ||||

Below 30st | 30st to 100st | 100st or Above | Below 30st | 30st to 100st | 100st or Above | ||

12 | 43 | 55 | 85 | 6 | 1 | 13 | 43 |

16 | 49 | 65 | 95 | 8 | 3 | 19 | 49 |

20 | 63 | 80 | 104 | 10 | 10 | 27 | 51 |

25 | 69.5 | 80.5 | 104.5 | 13 | 16 | 32 | 51 |

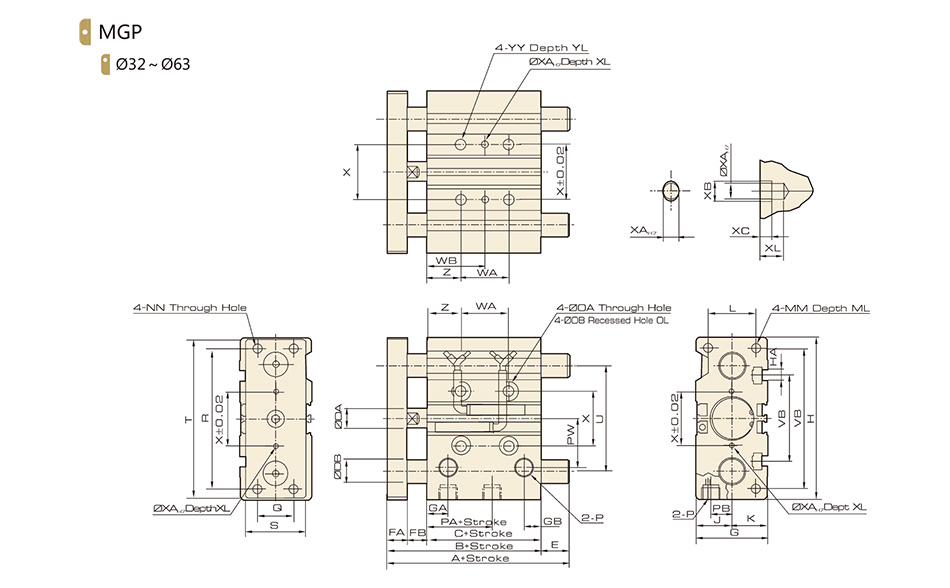

Overall Dimension

Dimension

MGPM, MGPL (Ø32~Ø63)

Bore (mm) | Standard Stroke | B | C | DA | FA | FB | G | GA | GB | GC | H | HA | J | K | L | MM | ML | NN | OA | OB | OL | P | PA | PB | PW | B |

32 | 25,50,75, 100,125, 150,175, 200 | 59.5 | 37.5 | 16 | 12 | 10 | 48 | 12.5 | 112 | 9 | 112 | M6 | 24 | 24 | 34 | M8×1.25 | 20 | M8×1.25 | 6.6 | 11 | 7.5 | Rc1/8 | 7 | 15 | 34 | 30 |

40 | 66 | 44 | 16 | 12 | 10 | 54 | 14 | 120 | 10 | 120 | M6 | 27 | 27 | 40 | M8×1.25 | 20 | M8×1.25 | 6.6 | 11 | 7.5 | Rc1/8 | 13 | 18 | 38 | 30 | |

50 | 72 | 44 | 20 | 16 | 12 | 64 | 12 | 148 | 11 | 148 | M8 | 32 | 32 | 46 | M10×1.5 | 22 | M10×1.5 | 8.6 | 14 | 9 | Rc1/4 | 9 | 21.5 | 47 | 40 | |

63 | 77 | 49 | 20 | 16 | 12 | 78 | 16.5 | 162 | 13.5 | 162 | M10 | 39 | 39 | 58 | M10×1.5 | 22 | M10×1.5 | 8.6 | 14 | 9 | Rc1/4 | 14 | 28 | 55 | 50 |

Bore (mm) | Standard Stroke | R | S | T | U | VA | VB | WA | WB | X | XA | XB | XC | XL | YY | YL | Z | ||||

| 25st | 50,75,100st | Above 100st | 25st | 50,75,100st | Above 100st | ||||||||||||||||

32 | 25,50,75, 100,125, 150,175, 200 | 96 | 44 | 110 | 78 | 98 | 63 | 24 | 48 | 124 | 33 | 45 | 83 | 42 | 4 | 4.5 | 3 | 6 | M8×1.25 | 16 | 21 |

40 | 104 | 44 | 118 | 86 | 106 | 72 | 24 | 48 | 124 | 34 | 46 | 84 | 50 | 4 | 4.5 | 3 | 6 | M8×1.25 | 16 | 22 | |

50 | 130 | 60 | 146 | 110 | 130 | 92 | 24 | 48 | 124 | 36 | 48 | 86 | 66 | 5 | 6 | 4 | 8 | M10×1.5 | 20 | 24 | |

63 | 130 | 70 | 158 | 124 | 142 | 110 | 28 | 52 | 128 | 38 | 50 | 88 | 80 | 5 | 6 | 4 | 8 | M10×1.5 | 20 | 24 | |

MGPM (Slidable Bearing)

Bore (mm) | A |

DB | E | ||

25,50st | Above 50st | Below 25,50st | Above 50st | ||

32 | 97 | 102 | 20 | 37.5 | 42.5 |

40 | 97 | 102 | 20 | 31 | 36 |

50 | 106.5 | 118 | 25 | 34.5 | 46 |

63 | 106.5 | 118 | 25 | 29.5 | 41 |

MGPL (Ball Bearing)

Bore(mm) | A | DB | E | ||||

50st | 75,100st | Above 100st | 50st | 75,100st | Above 100st | ||

32 | 81 | 98 | 118 | 16 | 21.5 | 38.5 | 58.5 |

40 | 81 | 98 | 118 | 16 | 15 | 32 | 52 |

50 | 93 | 114 | 134 | 20 | 21 | 42 | 62 |

63 | 93 | 114 | 134 | 20 | 16 | 37 | 57 |

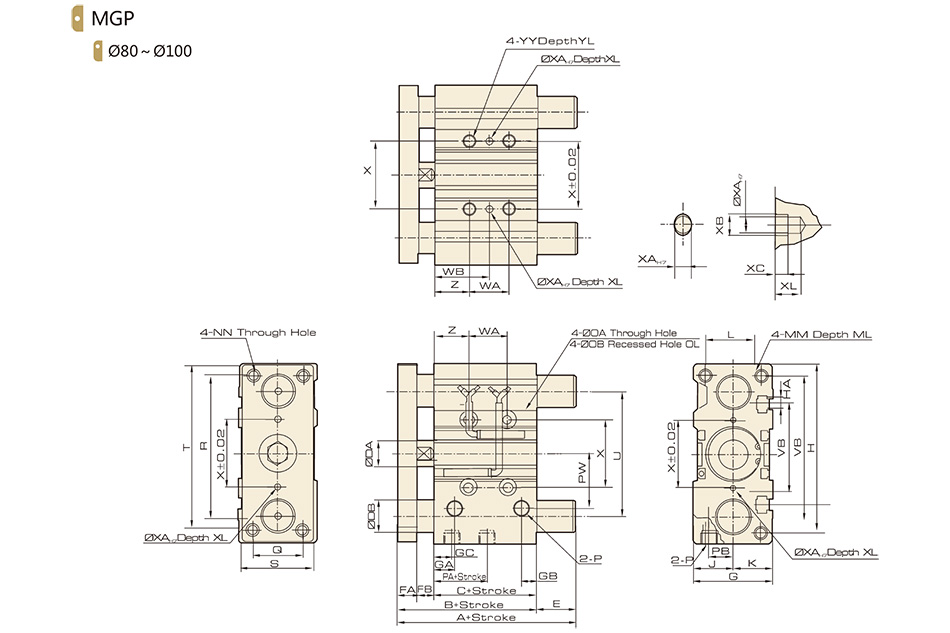

Overall Dimension

Dimension

MGPM, MGPL Dimension (Ø80~Ø100)

Bore (mm) | Standard Stroke | B | C | DA | FA | FB | G | GA | GB | GC | H | HA | J | JA | JB | K | L | MM | ML | NN | OA | OB | OL | P | PA | PB | PW | Q |

80 | 25,50,75, 100,125,150, 175,200 | 96.5 | 56.5 | 25 | 22 | 18 | 91.5 | 19 | 15.5 | 14.5 | 202 | M12 | 45.5 | 38 | 75 | 46 | 54 | M12×1.75 | 30 | M12×1.75 | 10.6 | 17.5 | 8 | Rc3/8 | 14.5 | 25.5 | 74 | 52 |

100 | 116 | 66 | 30 | 25 | 25 | 111.5 | 23 | 19 | 18 | 240 | M14 | 55.5 | 45 | 10.5 | 56 | 62 | M14×2.0 | 32 | M14×2.0 | 12.5 | 20 | 8 | Rc3/8 | 17.5 | 32.5 | 89 | 64 |

Bore (mm) | Standard Stroke | R | S | T | U | VA | VB | WA | WB | X | XA | XB | XC | XL | YY | TL | YZ | ||||

25st | 50,75,100st | Above 100st | 25st | 50,75,100st | Above 100st | ||||||||||||||||

80 | 25,50,75, | 174 | 75 | 198 | 156 | 180 | 140 | 28 | 52 | 128 | 42 | 54 | 92 | 100 | 6 | 7 | 5 | 10 | M12×1.75 | 24 | 28 |

100 | 210 | 90 | 236 | 188 | 210 | 166 | 48 | 72 | 148 | 35 | 47 | 85 | 124 | 6 | 7 | 5 | 10 | M14×2.0 | 28 | 11 | |

MGPM (Slidable Bearing)

Bore (mm) | A | DB | E | ||

25,50st | Above 50st | Below 25,50st | Above 50st | ||

80 | 115 | 142 | 30 | 18.5 | 45.5 |

100 | 137 | 162 | 36 | 21 | 46 |

MGPL (Ball Bearing)

Bore (mm) | A | DB | E | ||||

25,50st | 75,100st | Above 100st | 25,50st | 75,100st | Above 100st | ||

80 | 109.5 | 130 | 160 | 25 | 13 | 33.5 | 63.5 |

100 | 121 | 147 | 180 | 30 | 5 | 31 | 64 |