SI Serisi ISO15552 Silindir

Ürünler

Features

1. The cylinder is in accordance with the ISO15552.

2. The piston seal adopts two NBR+PA material as Y type one-way sealing structure with compensation function, long service life and low starting pressure.

3. The rod seal uses PU material with the characteristics of high strength, good toughness, wear resistance,oil resistance and aging resistance.

4. The piston rod material is made by 45C Carbon Steel with hard chrome plating on the surface, and the roughness Ra<0.4, with good wear

resistance and rust resistance.

![]()

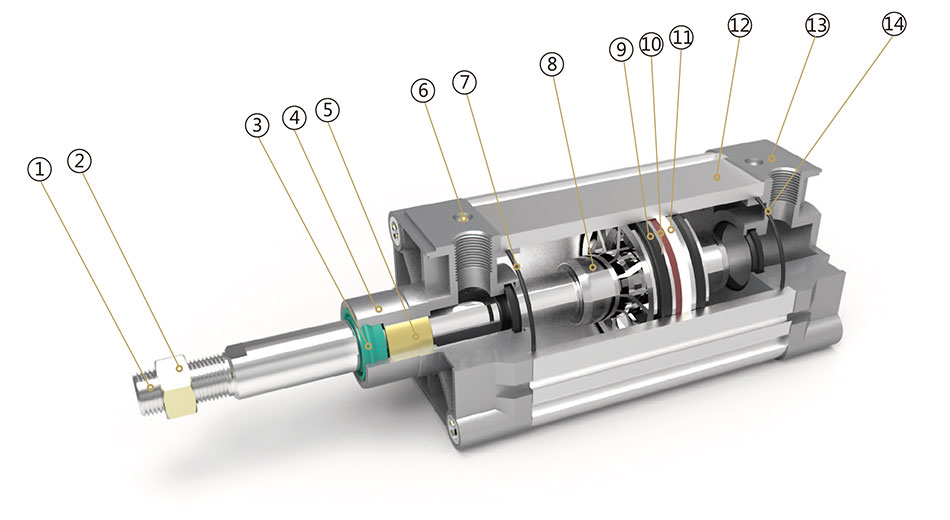

Internal Structure

Parts

Number | Name | Number | Name |

1 | Piston rod | 8 | Piston |

2 | Hexagon nut | 9 | Yring |

3 | Shaft seal | 10 | Magnet |

4 | Front cover | 11 | Anti-friction ring |

5 | Copper tube | 12 | Barrel |

6 | Cushion adjust screw | 13 | Back cover |

7 | Cushion seal | 14 | 0 ring |

![]()

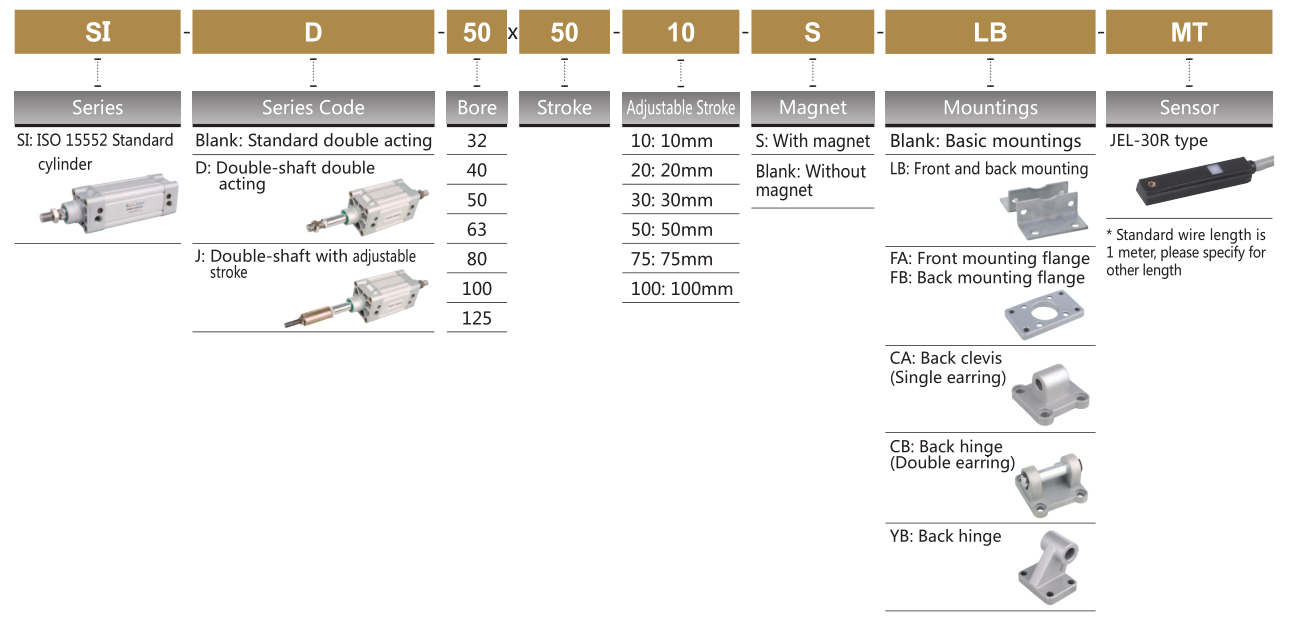

Ordering Code

![]()

Specification

Bore (mm) | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

Operation | Double Acting | ||||||

Working Medium | Air | ||||||

Mountings | Basic FA FB CA CB LB YB | ||||||

Operating Pressure Range | 1~9.0 Kgf/cm² | ||||||

Proof Pressure | 13.5 Kgf/cm² | ||||||

Operating Temperature Range | -20~80℃ | ||||||

Operating Speed Range | 50~800mm/s | ||||||

Cushion | Adjustable Cushion | ||||||

Adjustable Cushion Stroke | 20 mm | 26 mm | |||||

Port Size | G1/8″ | G1/4″ | G3/8″ | G1/2″ | |||

![]()

Stroke

Bore | Standard Stroke | Max. Stroke | Allowable Stroke |

32 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 | 1000 | 2000 |

40 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 | 1200 | 2000 |

50 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1200 | 2000 |

63 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

80 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

100 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

125 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 2000 |

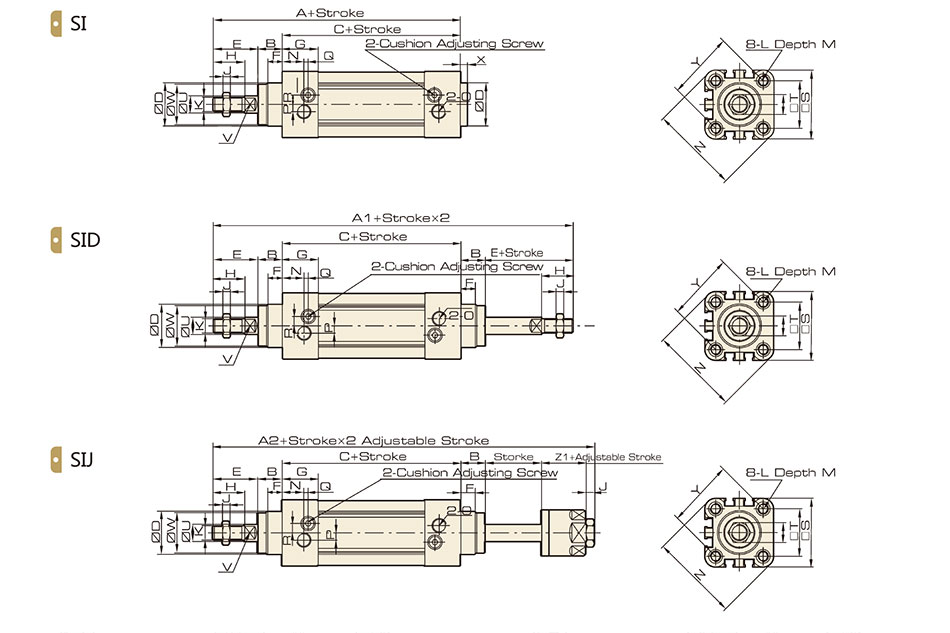

Overall Dimension

Dimension

Bore/ Symbol | A | A1 | A2 | B | C | D | E | F | G | H | I | J | K | L |

32 | 142 | 190 | 185 | 16 | 94 | 30 | 33 | 10 | 25 | 22 | 17 | 6 | M10x1.25 | M6 |

40 | 159 | 213 | 207 | 20 | 105 | 35 | 34 | 10 | 29 5 | 24 | 17 | 7 | M12x125 | M6 |

50 | 175 | 244 | 233 | 27 | 106 | 40 | 42 5 | 10 | 32 | 32 | 23 | 8 | M16x1.5 | M8 |

63 | 190 | 258 | 247 | 26 | 122 | 45 | 42 | 10 | 36 | 32 | 23 | 8 | M16x1.5 | M8 |

80 | 214 | 301 | 288 | 35 | 126 | 45 | 53 | 10 | 37 | 40 | 26 | 10 | M20x1.5 | M10 |

100 | 229 | 321 | 308 | 40 | 137 | 55 | 52 | 10 | 39 | 40 | 26 | 10 | M20x1.5 | M10 |

125 | 277 | 394 | 378 | 47 | 160 | 60 | 71 | 10 | 43 | 54 | 40 | 10 | M27x2 | M12 |

Bore/ Symbol | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | Z1 |

32 | 12 | 15 | G1/8 | 5 | 3 | 65 | 45 | 32 5 | 12 | 10 | 28 | 4 | 46 | 58 7 | 21 |

40 | 12 | 17 5 | G1/4 | 7 | 3 | 7 | 52 | 38 | 16 | 13 | 33 | 4 | 53 7 | 68 | 21 |

50 | 12 | 20 | G1/4 | 7 | 3 | 9 | 65 | 46.5 | 20 | 17 | 38 | 4 | 65.8 | 84.5 | 23 |

63 | 12 | 22 | G3/8 | 8 | 5 | 9 | 76 | 56.5 | 20 | 17 | 38 | 4 | 79.9 | 99.6 | 23 |

80 | 15 | 23 | G3/8 | 10 | 5 | 12 | 94 | 72 | 25 | 22 | 43.5 | 4 | 101.8 | 123.8 | 29 |

100 | 15 | 26 | G1/2 | 10 | 5 | 14 | 112 | 89 | 25 | 22 | 47 | 4 | 125 9 | 148 9 | 29 |

125 | 20 | 29 | G1/2 | 10 | 5 | 14 | 134 | 110 | 32 | 27 | 53 | 6 | 156.9 | 179.6 | 40.5 |

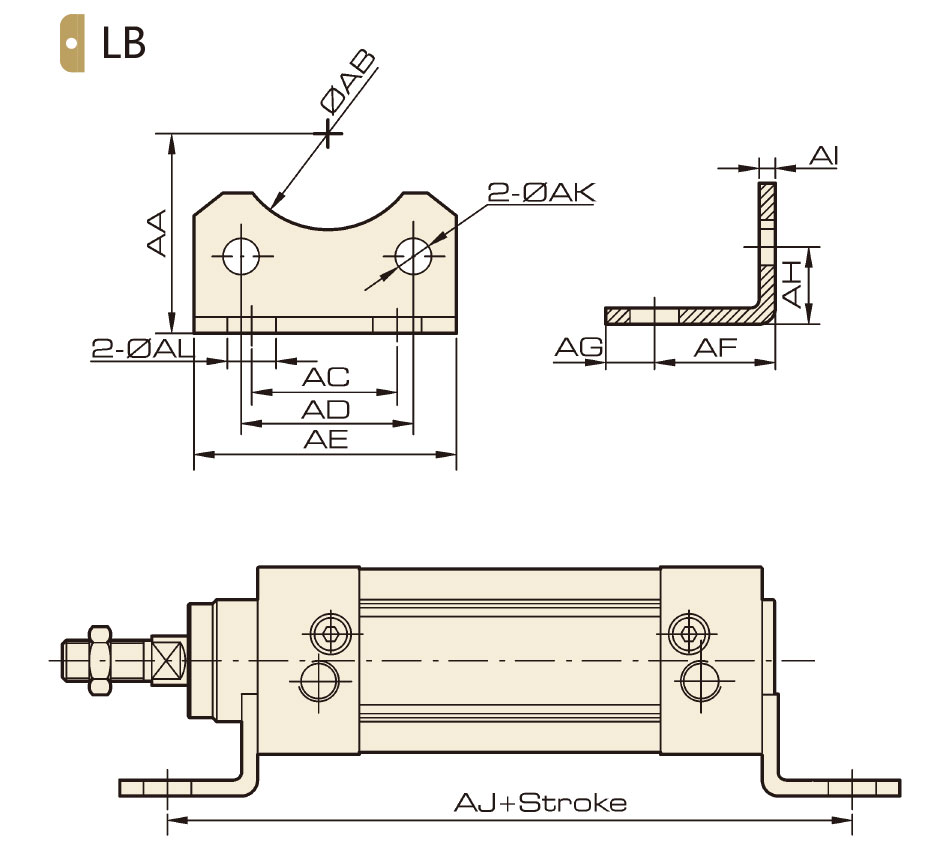

SI Series Standard Cylinder Accessory(Conforms to ISO15552 Standard)

Overall Dimension

LB Foot

Dimension

Bore/Symbol | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

AA | 32 | 36 | 45 | 50 | 63 | 71 | 90 |

AB | 30 | 35 | 40 | 45 | 45 | 55 | 60 |

AC | 32 | 36 | 45 | 50 | 63 | 75 | 90 |

AD | 32.5 | 38 | 46.5 | 56.5 | 72 | 89 | 110 |

AE | 45 | 52 | 65 | 75 | 95 | 115 | 140 |

AF | 24 | 28 | 32 | 32 | 41 | 41 | 45 |

AG | 11 | 8 | 15 | 13 | 14 | 16 | 18 |

AH | 15.8 | 17 | 21.8 | 21.8 | 27 | 26.5 | 35 |

AI | 4 | 4 | 5 | 5 | 6 | 6 | 8 |

AJ | 142 | 161 | 170 | 186 | 208 | 219 | 250 |

AK | 7 | 7 | 9 | 9 | 11 | 11 | 12.5 |

AL | 7 | 10 | 10 | 10 | 12 | 14.5 | 16.5 |

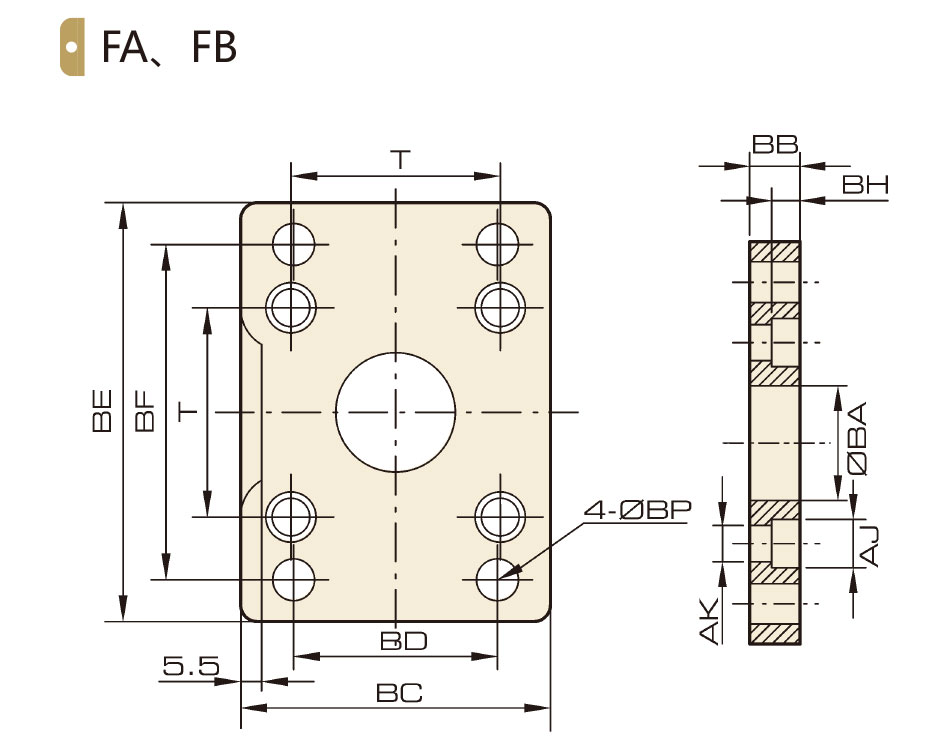

Overall Dimension

FA / FB Flange

Dimension

Bore/Symbol | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

BA | 30.3 | 35.3 | 40.3 | 45.3 | 45.3 | 55 3 | 60.3 |

BB | 10 | 10 | 12 | 12 | 16 | 16 | 20 |

BC | 45 | 52 | 65 | 76 | 94 | 112 | 140 |

BD | 32 | 36 | 45 | 50 | 63 | 75 | 90 |

BE | 80 | 90 | 110 | 120 | 150 | 175 | 224 |

BF | 64 | 72 | 90 | 100 | 126 | 150 | 180 |

BH | 6.5 | 6.5 | 8.5 | 8.5 | 10 5 | 10 5 | 15 |

AJ | 10.5 | 10.5 | 13.5 | 13.5 | 16.5 | 16.5 | 19 |

AK | 6.5 | 6.5 | 8.5 | 8.5 | 10.5 | 10.5 | 12.5 |

BP | 7 | 9 | 9 | 9 | 12 | 14 | 16 |

T | 32.5 | 38 | 46.5 | 56.5 | 72 | 89 | 110 |

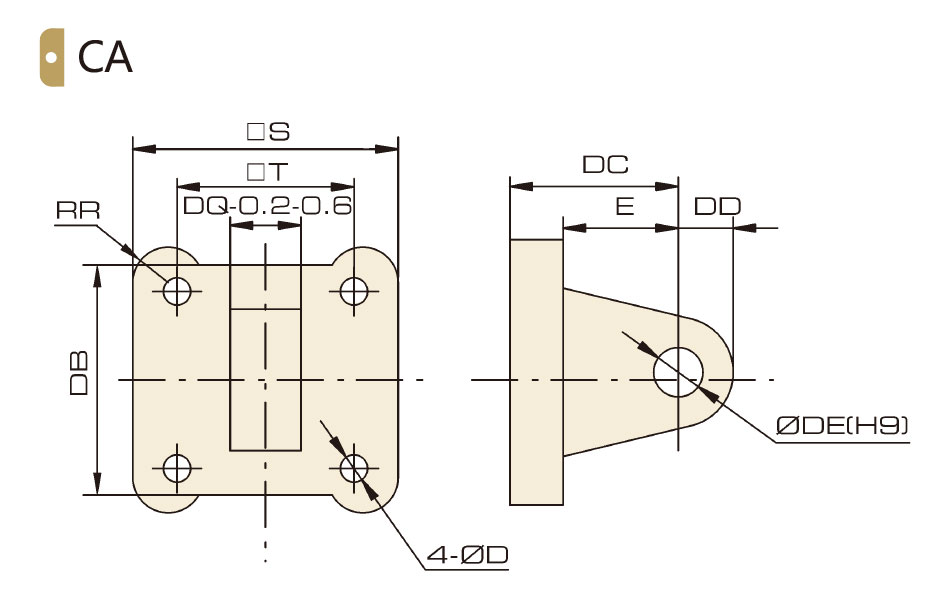

Overall Dimension

CA Hinge

Dimension

Bore/Symbol | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

S | 45 | 52 | 65 | 76 | 94 | 112 | 140 |

T | 32.5 | 38 | 46.5 | 56.5 | 72 | 89 | 110 |

RR | 6.5 | 6.5 | 9 | 9.5 | 11 | 11.5 | 12 |

DB | 34 | 41 | 54 | 65 | 83 | 101 | 123 |

DC | 22 | 25 | 27 | 32 | 36 | 41 | 50 |

DD | 10 | 11 | 13 | 16 | 16 | 20 | 25 |

DE | 10 | 12 | 12 | 16 | 16 | 20 | 25 |

DQ | 26 | 28 | 32 | 40 | 50 | 60 | 70 |

D | 6.5 | 6.5 | 8.5 | 8.5 | 10 5 | 10 5 | 12.5 |

E | 14 | 17 | 17 | 22 | 24 | 25 | 30 |

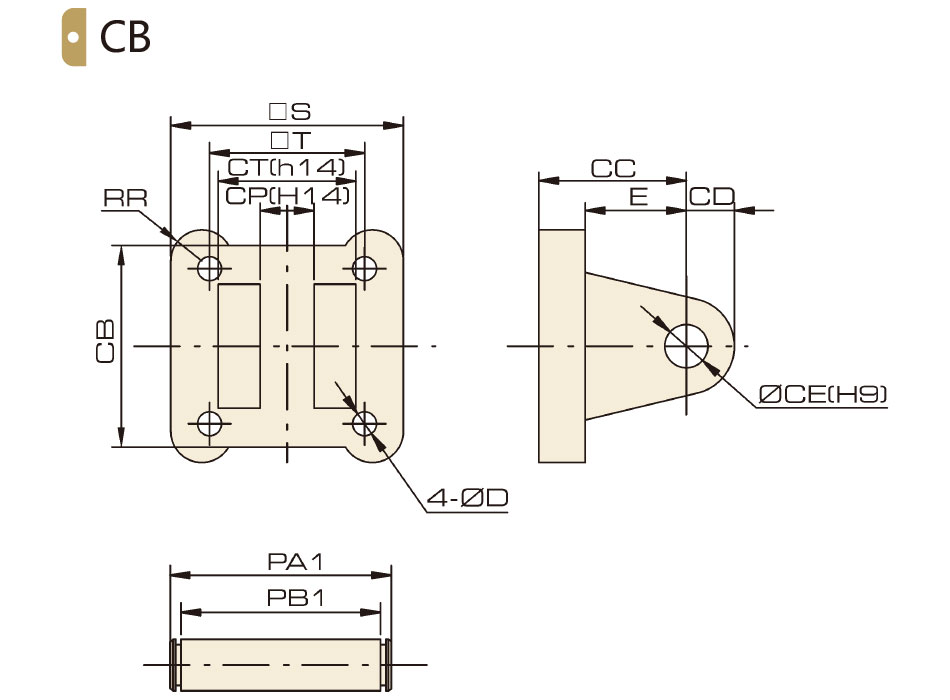

Overall Dimension

CB Hinge

Dimension

Bore/Symbol | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

S | 45 | 52 | 65 | 76 | 94 | 112 | 140 |

T | 32.5 | 38 | 46.5 | 56.5 | 72 | 89 | 110 |

D | 6.5 | 6.5 | 8.5 | 8.5 | 10.5 | 10.5 | 12.5 |

E | 14 | 17 | 17 | 22 | 24 | 25 | 30 |

RR | 6.5 | 6.5 | 9 | 9.5 | 11 | 11.5 | 12 |

CB | 34 | 41 | 54 | 65 | 83 | 101 | 123 |

CC | 22 | 25 | 27 | 32 | 36 | 41 | 50 |

CD | 10 | 11 | 13 | 16 | 46 | 20 | 25 |

CE | 10 | 12 | 12 | 16 | 16 | 20 | 25 |

CP | 26 | 28 | 32 | 40 | 50 | 60 | 70 |

CT | 45 | 52 | 60 | 70 | 90 | 110 | 120 |

PA1 | 53 | 60 | 68 | 78 | 100 | 120 | 130 |

PB1 | 46.5 | 53.5 | 61.5 | 71.5 | 91.5 | 111.5 | 121.5 |

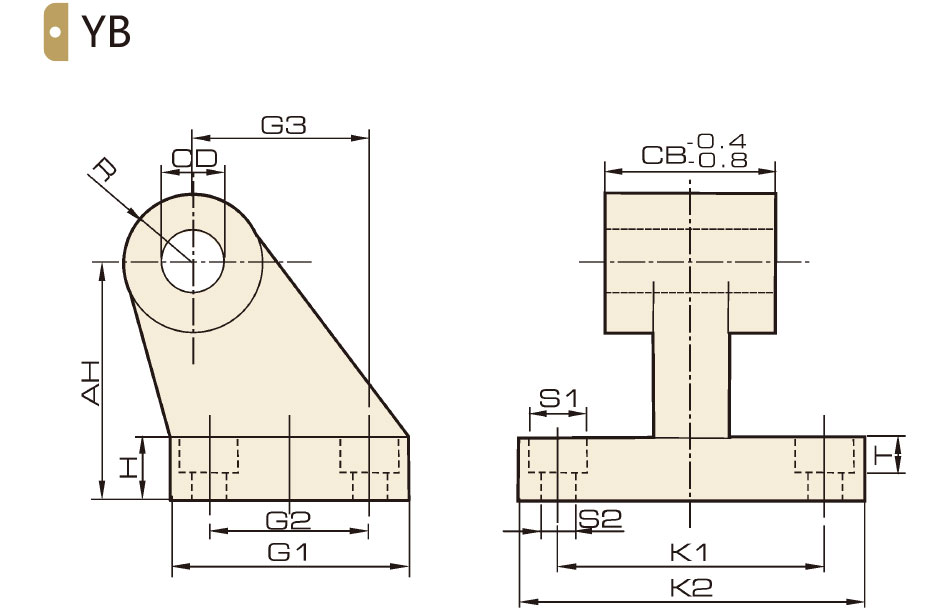

Overall Dimension

YB Hing

Dimension

Bore/Symbol | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

AH | 32 | 36 | 45 | 50 | 63 | 71 | 90 |

H | 8 | 10 | 12 | 12 | 14 | 15 | 20 |

CD | 10 | 12 | 12 | 16 | 16 | 20 | 25 |

G1 | 31 | 35 | 45 | 50 | 60 | 70 | 90 |

G2 | 18 | 22 | 30 | 35 | 40 | 50 | 60 |

G3 | 21 | 24 | 33 | 37 | 47 | 55 | 70 |

CB | 26 | 28 | 32 | 40 | 50 | 60 | 70 |

K1 | 38 | 41 | 50 | 52 | 66 | 76 | 94 |

K2 | 51 | 54 | 65 | 67 | 86 | 96 | 124 |

SI | 11 | 11 | 14 | 14 | 17 | 17 | 20 |

S2 | 6.6 | 6.6 | 9 | 9 | 11 | 11 | 14 |

T | 1.6 | 1.6 | 1.6 | 1.6 | 2.5 | 2.5 | 3.2 |

R | 10 | 11 | 13 | 15 | 15 | 19 | 22.5 |